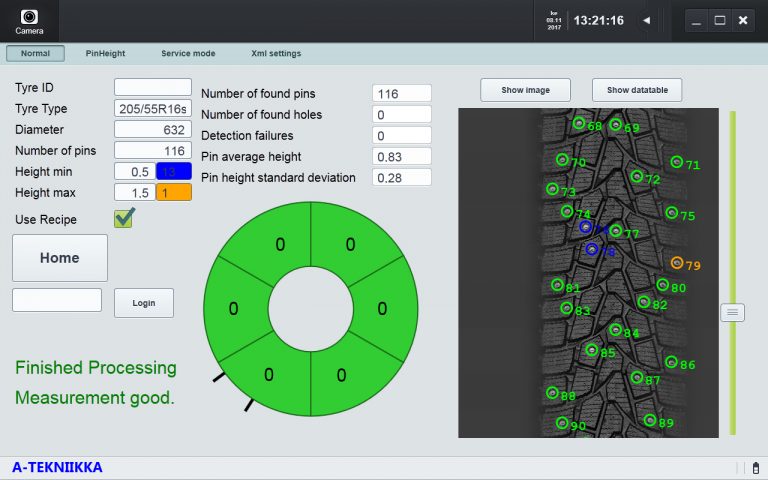

A-TEC 1000 – Studding quality control

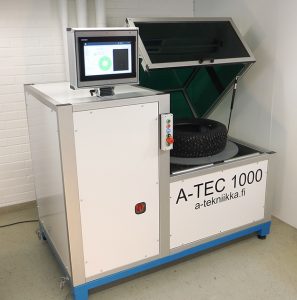

A-TEC 1000 is automatic stud protrusion measuring machine which also detects the missing studs from the tire. It is designed to improve the quality control in the tire factories. The A-TEC 1000 is available in two models: standard and movable compact model.

Machine functions:

• Scanning the tread surface of the tire (360°)

• Searches the studs and missed holes

• Draws the stud protrusion as a point chart from the datatable

• Shows the image of the tread surface on the operation panel with circles around the studs or the holes (with index numbering)

• Possibility to send the measurement data to company’s database

• Scanning sequence takes 20s (13” tyre)-40s (20” tyre)

Tyre sizes:

• 13” – 22” and Ø530mm – Ø900mm

• Maximum width of the scanning area 300mm

Measurement device:

• 3D-smart profile sensor

Accuracy:

• The average accuracy for stud protrusion varies ±0.01mm

• Single stud protrusion varies ±0.02mm

• One picture (50mm) has 1000×1280 datapoints (trigger spacing 0.05mm)